Introduction to Custom Foam Inserts

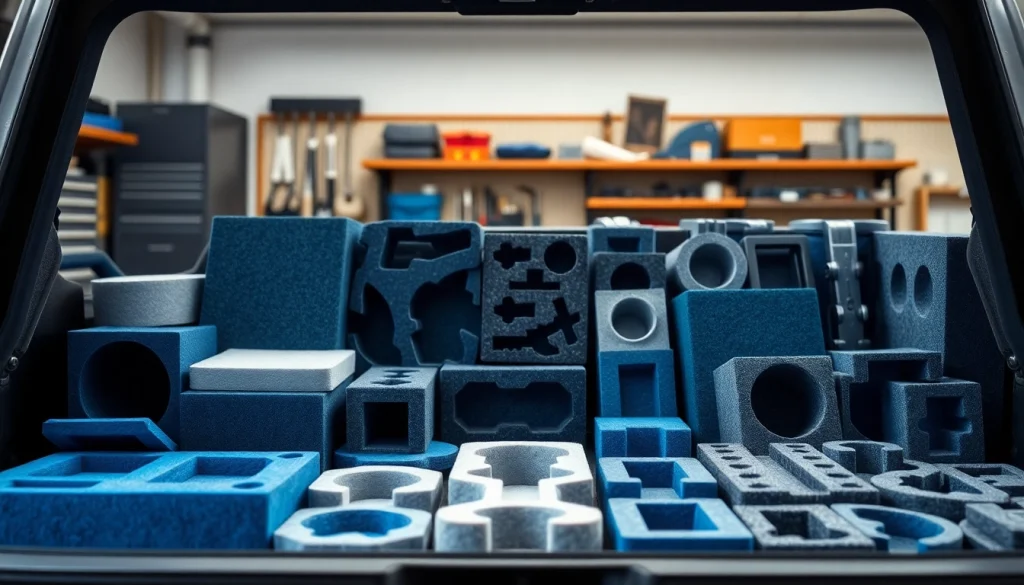

In an ever-evolving world where quality and protection of goods are paramount, Custom Foam Inserts have emerged as a vital solution. These inserts are specifically designed to cater to individual packaging needs, ensuring that items remain secure during transport, whether it’s delicate electronics, valuable tools, or intricate instruments. The customization aspect allows for versatility, offering tailored solutions that enhance both functionality and aesthetics.

Understanding Their Significance

The primary significance of custom foam inserts lies in their ability to protect and organize products efficiently. They serve not just as cushioning but also as mechanisms to segregate various items within a single packaging unit. This is crucial in minimizing movement, reducing damage risks, and optimizing storage space. In sectors ranging from healthcare to shipping, the right foam insert can mean the difference between a product arriving safely or being damaged beyond repair.

Common Materials Used

Custom foam inserts can be constructed from a variety of materials, each offering specific benefits. The most common materials include:

- Polyethylene Foam: Known for its lightweight and durable properties, this foam provides excellent cushioning and is resistant to moisture and chemicals.

- Polyurethane Foam: This is a versatile option characterized by its softness and ability to absorb impact effectively, making it ideal for fragile items.

- Memory Foam: While primarily used in residential applications, memory foam can also be utilized for custom inserts when superior shock absorption is needed.

- Anti-Static Foam: Essential for electronics, this foam prevents static electricity from damaging sensitive components.

- Cross-Linked Foam: This type offers enhanced durability and is often used in industrial applications due to its high resistance to wear and tear.

Selecting the right material is crucial for ensuring that the insert meets specific requirements in terms of protection, weight, and environmental factors.

Applications Across Industries

Custom foam inserts have found applications in a wide range of industries, including:

- Electronics: From shipping laptops to protecting circuit boards, custom foam helps prevent damage during transit.

- Medical Equipment: Ensuring that delicate instruments and devices are securely housed while remaining easily accessible is vital in the healthcare sector.

- Automotive Parts: In the automotive industry, custom foam inserts are used for everything from vehicle storage to protecting critical components during shipping.

- Retail Packaging: As brands strive for premium packaging, custom foam inserts enhance the unboxing experience while safeguarding products.

- Military & Defense: Custom inserts are utilized to protect sensitive military equipment during transport, ensuring it remains operational under challenging conditions.

Benefits of Choosing Custom Foam Inserts

Protection Against Impact

The primary benefit of custom foam inserts is their ability to protect products from impact. Designed to absorb shocks and vibrations, these inserts are pivotal in maintaining the integrity of sensitive items. By cushioning products effectively, they minimize the risk of damage due to jostling that can occur during shipping and handling. This structural protection is especially critical for delicate tools, electronics, and fragile materials, significantly reducing the likelihood of costly returns or replacements.

Organizational Efficiency

Custom foam inserts not only protect but also improve organizational efficiency. By providing designated spaces for each item, they facilitate easier retrieval and inventory management. Users can quickly identify where each item belongs, reducing search times and streamlining workflows. This organization is particularly beneficial in high-volume shipping environments where efficiency translates directly into cost savings and improved customer satisfaction.

Cost-Effectiveness

Investing in custom foam inserts is a cost-effective strategy for many businesses. The expense of damaged items, lost sales, and returns can quickly outweigh initial savings achieved by using lower-quality packaging solutions. Custom foam inserts help mitigate costly damages while enhancing the overall presentation of products. Furthermore, the longer lifespan of quality foam means that businesses often enjoy better value over time, aligning quality with fiscal responsibility.

How to Choose the Right Custom Foam Inserts

Identifying Your Needs

The first step in selecting custom foam inserts is to thoroughly assess your specific needs. Consider factors such as the type of items being packaged, the level of protection required, shipping conditions, and customer expectations. For example, fragile electronics will necessitate robust cushioning solutions versus heavier items that require less delicate care. Documenting these requirements will serve as a foundation for the entire design process.

Evaluating Foam Types

Once needs are defined, evaluating the appropriate foam types is paramount. Each material comes with its advantages and should be selected based on the specific requirements documented earlier. For instance, if moisture resistance is a factor, choosing polyethylene over polyurethane might be advantageous. Similarly, anti-static foam should be prioritized for sensitive electronics. Understanding these distinctions ensures that the final insert provides optimal performance.

Hyper-Specific Design Considerations

Creating truly custom foam inserts requires attention to hyper-specific design considerations, such as the dimensions of your items, weight distribution, and ease of handling. Prototyping often plays a crucial role here. Consider if a pick-and-pull style is beneficial, or whether individual custom cavities are more suitable. The ability to visualize and model different designs using digital tools can significantly enhance the effectiveness of the final product.

Creating Your Custom Foam Inserts

Design Process Overview

The design process for custom foam inserts typically involves several key steps: initial concept development, detailed design, and prototyping. During the concept phase, it’s essential to gather input from all stakeholders, including operational personnel who will use the packaging regularly. Following this, creating detailed technical drawings ensures that everyone is aligned before moving into prototyping.

Tools and Software You Can Use

Utilizing the right tools and software can streamline the design of custom foam inserts. CAD (Computer-Aided Design) software allows for precise modeling of foam inserts, meaning modifications can be made quickly and efficiently. Simulation tools can also provide insights into how designs will perform under various conditions, allowing for adjustments before physical prototypes are created.

Prototyping and Testing

Prototyping is a critical step in ensuring that the design translates well into a functional product. Creating a prototype allows for testing in real-world scenarios, identifying any potential issues before mass production. During this phase, it’s vital to evaluate all aspects—from fit to protection levels—ensuring that the insert meets the established requirements adequately.

FAQs about Custom Foam Inserts

What are the typical uses of Custom Foam Inserts?

Custom Foam Inserts are typically used for packaging electronics, medical devices, and tools, providing protection and organization during transport and storage.

How long do custom foam inserts last?

The lifespan of custom foam inserts varies by material and environment, but quality foam can last several years with proper care, maintaining its protective properties.

Can I order small quantities of Custom Foam Inserts?

Many manufacturers offer flexible ordering options, including small quantities, allowing for customized solutions tailored to individual or lower volume needs.

What materials are best for moisture resistance?

Polyethylene foam is highly moisture-resistant, making it a solid choice for applications where exposure to humidity or liquids may occur.

Are custom foam inserts environmentally friendly?

Many modern foam options come from recyclable materials and are designed to be environmentally friendly, reducing their overall ecological footprint.